Not sure where to begin with your invention design?

Get FREE Info NOW!

Resource Articles

How to Get a Prototype Made

By MarketBlast

Not sure where to begin with your invention design?

Get FREE Info NOW!

Why

Prototyping is Key for Inventors

Every

invention begins as an idea, but to transform that idea into a viable product,

you need more than just a mental image or a drawing on paper—you need a

prototype. Prototyping allows you to see how your invention will look and

function in the real world. It's a process that offers clarity, fosters

creativity, and can highlight the potential flaws or areas for improvement in

your design.

The

question most inventors face is: how do you actually get a prototype made?

Whether you’re a first-time inventor or a seasoned creator, understanding the

steps and strategies for prototyping can make the difference between a concept

that remains on the drawing board and a product that succeeds in the market. In

this article, we’ll walk you through the entire process of getting a prototype

made, from brainstorming and design to materials, costs, and finding the right

professionals to bring your invention to life.

Why

a Prototype Is Important

Before

diving into the "how," let’s clarify why having a prototype is so

essential:

Proof

of Concept

A prototype demonstrates that your

idea works. It’s a tangible representation that proves your invention can

function as intended. This can help you make adjustments, solve unforeseen

problems, and refine your design before it reaches the manufacturing stage.

Patent

and Legal Protection

Prototypes are often needed to support

your patent application. They can serve as proof that your invention is viable

and unique, which can strengthen your claim when applying for a patent.

Investor

and Manufacturer Attraction

If you want to attract investors or

manufacturers, a prototype is invaluable. Being able to show a potential

partner what your product looks like and how it works will increase their

confidence in your project. It turns your idea into something they can see,

touch, and test.

Market

Feedback

A prototype allows you to test your

invention in the real world. You can use it to gather feedback from potential

customers or focus groups, helping you make changes and improvements that align

with market needs before full production.

Steps

to Get a Prototype Made

The

prototyping process might feel overwhelming, but breaking it down into

manageable steps makes it more accessible. Let’s explore each of these steps in

detail.

Define

Your Objective

Before

you start building your prototype, you need to clearly define what you want to

achieve with it. Are you looking to create a simple proof of concept to test

functionality, or do you need a working model that closely resembles the final

product?

There

are different types of prototypes, including:

- Concept

Prototypes: These are basic

models that demonstrate the core functionality of your idea without focusing on

design or materials.

- Working

Prototypes: These models not

only show the design but also simulate the actual function of the product.

- Final

Prototypes: The final

versions are usually fully functional and made from materials that closely

resemble the final product.

Knowing

your goal will help guide the materials, time, and resources needed for the

prototype.

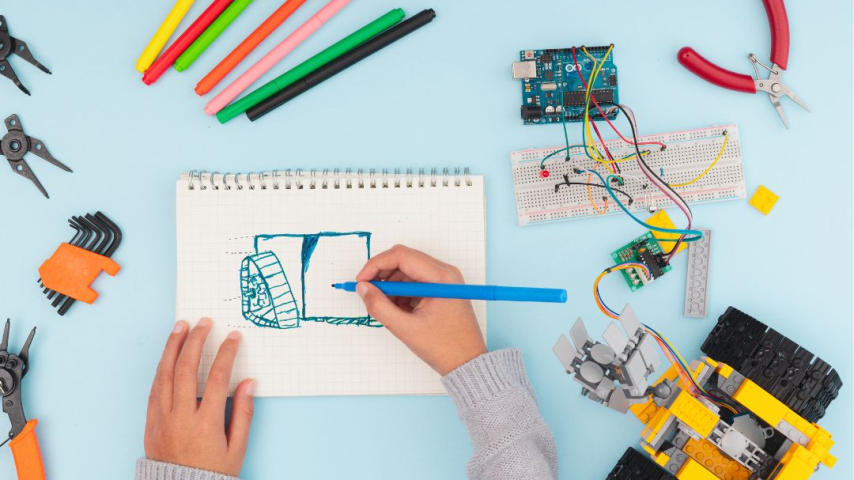

Sketch

and Design Your Prototype

The

first step in creating a physical version of your idea is to sketch it out. You

don’t have to be a professional artist—just draw your invention from different

angles and highlight its key features. Focus on how the different components

will work together. Include measurements, materials, and any functional details

that will help you (and eventually, a professional) bring the prototype to

life.

Once

you’ve created a rough sketch, you may want to move to a digital design tool

for greater precision. Computer-Aided Design (CAD) software is commonly used

for this step. CAD allows you to create a 3D model of your invention, which can

be used later for advanced prototyping techniques such as 3D printing or

machining. If you’re unfamiliar with CAD software, you might want to hire a

freelance designer or a prototyping company to assist you.

Popular

tools and software for design include:

- Fusion 360

- SolidWorks

- AutoCAD

- Tinkercad (for beginners)

Choose

the Right Materials

The

materials you choose for your prototype will depend on the complexity of your

invention, your budget, and the prototype’s intended purpose. If you’re

building a simple proof of concept, you may be able to use inexpensive

materials like cardboard, plastic, or even household items. If you need a more

advanced prototype, you may require specialized materials such as metal,

high-grade plastics, or electronics.

Considerations

when selecting materials:

- Durability: Will the prototype need to be tested multiple

times or withstand certain conditions (heat, pressure, etc.)?

- Functionality: Does your invention require specific parts to

be flexible, sturdy, or conductive?

- Cost: Some materials are expensive, especially for early-stage prototyping, so it’s important to find a balance between quality and cost-efficiency.

Not sure where to begin with your invention design?

Get FREE Info NOW!

Build

a Proof of Concept

At

this stage, you’ll create your first version of the prototype. For many

inventors, this will be a basic proof of concept designed to test the core

functionality of the idea. Depending on the complexity, you can try building

the prototype yourself or hire a professional.

DIY

Prototyping

For

simple inventions, many inventors choose to build their first prototype

themselves. This can be done using affordable tools like:

- 3D

printers: Many hobbyists and small businesses

have adopted 3D printing as an efficient and cost-effective way to create

prototypes.

- Moldable

plastics: Products like Sugru or InstaMorph

allow inventors to easily create or alter parts.

- Electronics

kits: For inventions involving circuits or

sensors, kits like Arduino or Raspberry Pi can be invaluable for DIY

electronics.

DIY

prototyping is cost-effective and gives you a hands-on understanding of how

your invention works. However, it may not be suitable for more complex

products.

Professional

Prototyping Services

For

more advanced prototypes, you may need to hire a professional or use a

prototyping service. These professionals can take your design and create a

working model using techniques like machining, laser cutting, or injection

molding. Many companies specialize in helping inventors bring their prototypes

to life.

Prototyping

firms typically offer services like:

3D

printing for precise, detailed models

Machining

for durable parts, especially metal

Injection

molding for parts that need to be manufactured in larger quantities

Some

companies that specialize in prototyping include:

- ProtoLabs

- Fictiv

- Xometry

- 3D Hubs

Test

and Refine the Prototype

Once

you have a working prototype, it’s time to test it rigorously. Here are the key

things to focus on during the testing phase:

- Functionality: Does it work as intended? Are there any

design flaws?

- User

Experience: Is it easy to

use? Does it fulfill the need it’s designed to solve?

- Durability: How well does it hold up under stress or

extended use?

Based

on the testing results, you will likely need to make adjustments. The

prototyping process is often iterative, meaning you’ll go through several

rounds of testing and refinement before arriving at a final version.

Create

a Final, Production-Ready Prototype

After

refining your design, the next step is to create a final prototype that is

ready for production. This version should be nearly identical to the product

you intend to manufacture and sell. It should be built using the same materials

and methods that will be used in mass production.

At

this stage, you might also start considering manufacturing costs, supplier

sourcing, and the logistics of bringing your product to market.

Costs

and Timeline for Prototyping

The

cost of getting a prototype made varies widely depending on the complexity of

the invention and the type of materials used. Here’s a rough breakdown of what

to expect:

Basic

DIY Prototype: $100 – $500

3D

Printed Prototype: $300 – $5,000

Machined

Prototype: $1,000 – $10,000+

Injection

Molded Prototype: $5,000 – $50,000+

The

timeline for creating a prototype can also vary. A simple DIY prototype might

only take a few days or weeks, while a more complex, professional prototype can

take several months to complete.

Working

with Prototyping Companies: What to Look For

When

selecting a prototyping company or service, there are a few key factors to

consider:

Experience: Look for companies with experience in your

industry or with products similar to yours.

Capabilities: Ensure they offer the specific services you

need, such as 3D printing, machining, or electronics.

Cost

Transparency: Ask for clear

estimates and understand what is included in their pricing.

Communication: A company that communicates well and

understands your vision will save you time and frustration.

Quality: Ask to see examples of their previous work to

ensure the quality of their prototypes meets your expectations.

Some

Final Thoughts: From Idea to Reality

Creating

a prototype is an exciting and vital step in the invention process. It takes

your idea from the theoretical stage and turns it into something you can see,

touch, and test. Whether you opt for a DIY approach or hire a professional

prototyping firm, knowing how to get a prototype made can significantly

increase your chances of success in bringing your product to market.

By

following the steps outlined in this guide—defining your objective, designing a

model, choosing materials, testing, refining, and creating a final

prototype—you’ll be well on your way to transforming your invention into a

reality.

Not sure where to begin with your invention design?

Get FREE Info NOW!

Founded with the vision to transform the

landscape for monetizing and commercializing innovative products and brands,

MarketBlast® is the leading Product Hunt and Submission Management Platform

connecting buyers and sellers across the globe. Since our inception, we have

been dedicated to empowering small companies, startups, entrepreneurs and

emerging brands to connect directly with industry companies and accelerate

their own marketing and sales efforts to achieve lasting results.

At MarketBlast®, we believe

that innovation thrives on collaboration. Our platform provides seamless access

to a diverse network of companies, proprietary content marketing and

advertising programs, and access to a wide range of resources designed to

support the overall journey toward success.

For more information on signing up for a

premium membership or to start a content marketing campaign for your products,

email info@marketblast.com or

visit www.marketblast.com.

Other

Related Articles

How Do You Get

a Prototype of Your Invention Made?

Do You Need an

Invention Prototype?

How Much Does

It Cost to Design a Logo?

Can Developing

a Prototype for Your Invention Help You Succeed

Do You need a

Prototype for Your Invention