- Bring Your Idea to Life -

Get Your Free Product Design Info Today!

Resource Articles

Product Design and Prototyping

By MarketBlast

- Bring Your Idea to Life -

Get Your Free Product Design Info Today!

The

Bridge Between Concept and Reality

In

the world of product development, the path from an idea to a market-ready

product is filled with challenges, revisions, and breakthroughs. Product design

and prototyping are two critical steps in this journey. They allow creators to

breathe life into their concepts, transforming them into tangible products that

can be tested, refined, and eventually produced on a larger scale. These stages

are essential to building products that function as intended and are attractive

to consumers and feasible to manufacture.

Whether

you're an inventor, entrepreneur, or designer, mastering product design and

prototyping can significantly improve your product's chances of succeeding in

the marketplace. In this article, we'll explore the complete process, from

initial ideation to creating the first working prototype. We will provide

insights, tips, and best practices to guide your development journey.

What

Is Product Design?

Product

design is the process of conceptualizing and creating a product that solves a

particular problem or fulfills a specific need. It combines creativity,

engineering, and practicality, where aesthetics and functionality must

harmonize. Product design involves how the product looks and how it works,

feels, and interacts with the user.

Key

Aspects of Product Design:

User-Centered

Design

Every

successful product design process starts with the end-user in mind. Designers

must understand their target audience's needs, behaviors, and pain points to

create functional and appealing products. User-centered design ensures that the

product solves real problems and is intuitive.

Functionality

A

product must efficiently fulfill its primary purpose. Whether it's a consumer

gadget or a piece of industrial machinery, the design must prioritize function

over form without sacrificing ease of use. Designers need to think about how

the product will be used, how its features will work, and how it will perform

under real-world conditions.

Aesthetic

Appeal

A

product's design also plays a significant role in attracting customers. The way

a product looks—its shape, color, and texture—can be a powerful differentiator

in a crowded marketplace. While aesthetic elements should never overshadow

functionality, a visually appealing product will have a stronger presence on

store shelves and in customers' minds.

Feasibility

and Cost

Beyond

functionality and aesthetics, product design must also consider the

practicality of manufacturing. Designers must know the costs associated with

production materials, manufacturing processes, and distribution. A great design

is worthless if it's too expensive or complex to produce at scale.

The

Process of Product Design

Product

design is an iterative process that begins with a simple idea and evolves into

a detailed plan for a real-world product. Here's how the process typically

unfolds:

1.

Ideation and Concept Development

The

first step in product design is ideation, where the product concept is born.

Ideation is the process of brainstorming and generating ideas based on a

problem that needs solving or a market opportunity. During this phase,

exploring a wide range of possibilities without limitations is important,

encouraging creativity and innovation.

Once

several ideas have been generated, the next step is refining them into a

workable concept. This involves selecting the most promising ideas and

developing them further into rough sketches or simple diagrams. These concepts

can be discussed with key stakeholders, partners, or potential customers to

gather feedback and refine the direction.

2.

Market Research and Validation

After

a concept has been developed, market research is essential. This step involves

analyzing the target market, understanding competitor products, and gauging

consumer interest. Research tools like surveys, focus groups, and interviews

with potential users can provide valuable insights into whether the product

will be in demand and what features are most important.

Market

research helps you determine whether your product concept is viable. It can

also reveal gaps in the market that you can exploit to differentiate your

product from the competition.

3.

Sketching and Initial Design

Once

the concept has been validated through market research, designers move into the

sketching phase. This is where rough drawings are created to outline the

product's basic structure, form, and functionality. The goal is to capture the

product's essence without delving too deeply into technical details.

These

early sketches are meant to be exploratory and flexible. Designers may create

several versions to test different approaches and gather feedback. It's also an

excellent opportunity to experiment with the product's shape, size, and

ergonomic considerations.

4.

Digital Design (CAD)

After

the initial sketches are approved, the next step is to translate these concepts

into more detailed digital designs using Computer-Aided Design (CAD) software.

CAD programs, such as AutoCAD, SolidWorks, or Fusion 360, allow designers to

create precise 3D models of the product. These models enable engineers and

designers to visualize the product from all angles, simulate functionality, and

even calculate measurements for production.

Digital

designs also make it easier to test the product's functionality before creating

a physical prototype. Designers can run simulations to ensure all parts work

together seamlessly and avoid costly errors down the road.

5.

Design for Manufacturing

Designing

a product is only half the battle. The next challenge is ensuring that the

design can be manufactured efficiently and affordably. This is known as Design

for Manufacturing (DFM). During this stage, designers work with engineers and

manufacturers to adjust the product's design to suit large-scale production.

Factors

to consider during DFM include:

Material

Selection: Choosing cost-effective, durable, and

suitable materials for the product's intended use.

Manufacturing

Processes: Ensuring that the design can be

produced using standard manufacturing methods (e.g., injection molding, 3D

printing, CNC machining).

Assembly: Simplifying the product's design to reduce

the number of parts and streamline the assembly process.

- Bring Your Idea to Life -

Get Your Free Product Design Info Today!

What

Is Prototyping?

Prototyping

is the process of building an early version or sample of the product to test

its design, functionality, and overall performance. It bridges the conceptual

design phase and the final product launch, allowing designers, engineers, and

stakeholders to evaluate how the product performs in real-world conditions.

Types

of Prototypes

There

are several types of prototypes, each serving a specific purpose at different

stages of product development:

Proof

of Concept Prototype

A

proof-of-concept (PoC) prototype is a basic model that demonstrates the core

idea behind the product. This early prototype may not include all the features

or aesthetic details of the final product, but it proves that the concept

works. PoC prototypes are often created using simple materials like cardboard,

foam, or even 3D-printed components.

Working

Prototype

A

working prototype is a more advanced version that closely resembles the final

product's appearance and functionality. This type of prototype is used to test

how the product performs under real-world conditions. It includes all the

necessary features and components and is typically made from materials that

will be used in the final version.

Visual

Prototype

A

visual prototype focuses on the product's appearance rather than functionality.

It presents the product to stakeholders, investors, or potential customers,

showing how it will look. While it may not function, a visual prototype is

essential for gathering feedback on aesthetics and design.

Final

Prototype

The

final prototype is essentially a fully realized version of the product,

combining both functionality and aesthetics. It's the last iteration before

mass production and is used to ensure that the product meets all design,

performance, and manufacturing requirements.

The

Importance of Prototyping

Prototyping

is a crucial part of product development for several reasons:

Testing

and Refining the Design

Prototyping

allows designers to test their concepts in the real world. By building physical

models, they can see how the product functions, identify design flaws, and make

improvements. It's a chance to test everything from usability to durability

before moving into full-scale production.

Reducing

Risk

Building

a prototype reduces the risk of costly mistakes during production. By catching

issues early, you avoid expensive reworks and redesigns once manufacturing has

begun. Prototyping ensures the product is well-tested and ready for the

market's demands.

Gathering

Feedback

Prototypes

are also essential for gathering user feedback. Allowing potential customers,

investors, or stakeholders to interact with the product provides valuable

insights into its usability and appeal. This feedback can help you refine the

product before launch, ensuring it meets customer expectations.

Demonstrating

Feasibility to Stakeholders

A

functional prototype is a powerful tool when seeking investment or approval

from stakeholders. It shows that the concept is viable and close to production,

giving investors confidence in the product's potential.

The

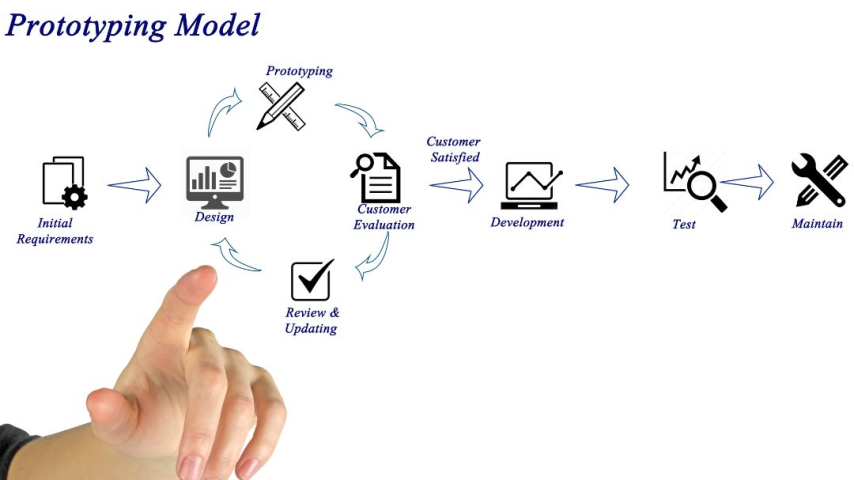

Prototyping Process

The

prototyping process typically follows several stages, each offering

opportunities to test and refine the product:

Build

an Initial Prototype

The

first step is creating an initial prototype, often a simple proof of concept.

This prototype helps designers and engineers test the product's basic

functionality and identify any major design flaws.

Test

and Gather Feedback

After

building the prototype, thorough testing is essential. This may involve user

testing, stress testing, and functionality testing to ensure the product

performs as expected.

Iterate

and Improve

The

product design may need to be modified based on feedback from testing.

Prototyping is an iterative process, meaning several rounds of revisions may be

necessary before the product is ready for production.

Build

the Final Prototype

Once

all issues have been addressed, the final prototype is built. This version

should be identical to the product that will be manufactured, both in

appearance and function.

Moving

from Prototyping to Production

Once

the final prototype has been approved, the product is ready for production. At

this stage, it's essential to work closely with manufacturers to ensure the

design is scalable and cost-effective. Design for Manufacturing principles come

into play here, helping to streamline production and reduce costs.

Final

Thoughts About Bringing Ideas to Life

Product

design and prototyping are at the heart of successful product development.

Together, these processes transform abstract concepts into tangible products,

ensuring that each detail—whether functional, aesthetic, or practical—has been

thoroughly tested and refined. By following a structured approach to design and

prototyping, inventors and businesses can reduce risks, maximize market

potential, and deliver products that stand out from the competition. Whether

you're at the ideation stage or building your first prototype, mastering these

steps will help bring your ideas to life.

- Bring Your Idea to Life -

Get Your Free Product Design Info Today!

Founded with the vision to transform the

landscape for monetizing and commercializing innovative products and brands,

MarketBlast® is the leading Product Hunt and Submission Management Platform

connecting buyers and sellers across the globe. Since our inception, we have

been dedicated to empowering small companies, startups, entrepreneurs and

emerging brands to connect directly with industry companies and accelerate

their own marketing and sales efforts to achieve lasting results.

At MarketBlast®, we believe

that innovation thrives on collaboration. Our platform provides seamless access

to a diverse network of companies, proprietary content marketing and

advertising programs, and access to a wide range of resources designed to

support the overall journey toward success.

For more information on signing up for a

premium membership or to start a content marketing campaign for your products,

email info@marketblast.com or

visit www.marketblast.com.

Other

Related Articles

How Do You Get

a Prototype of Your Invention Made?

Do You Need an

Invention Prototype?

How Much Does

It Cost to Design a Logo?

Can Developing

a Prototype for Your Invention Help You Succeed

Do You need a

Prototype for Your Invention